Microfluidic injection molding keys

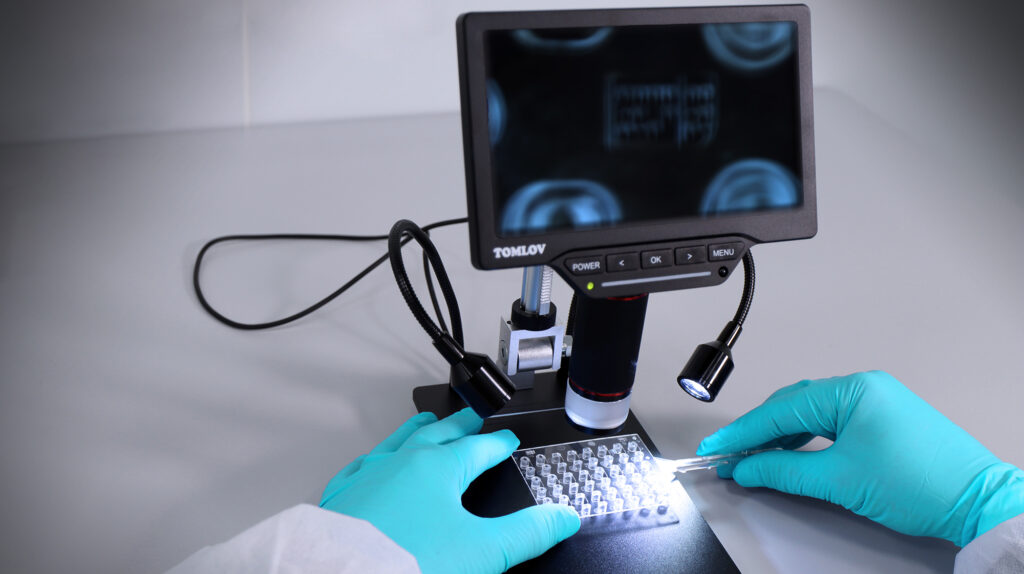

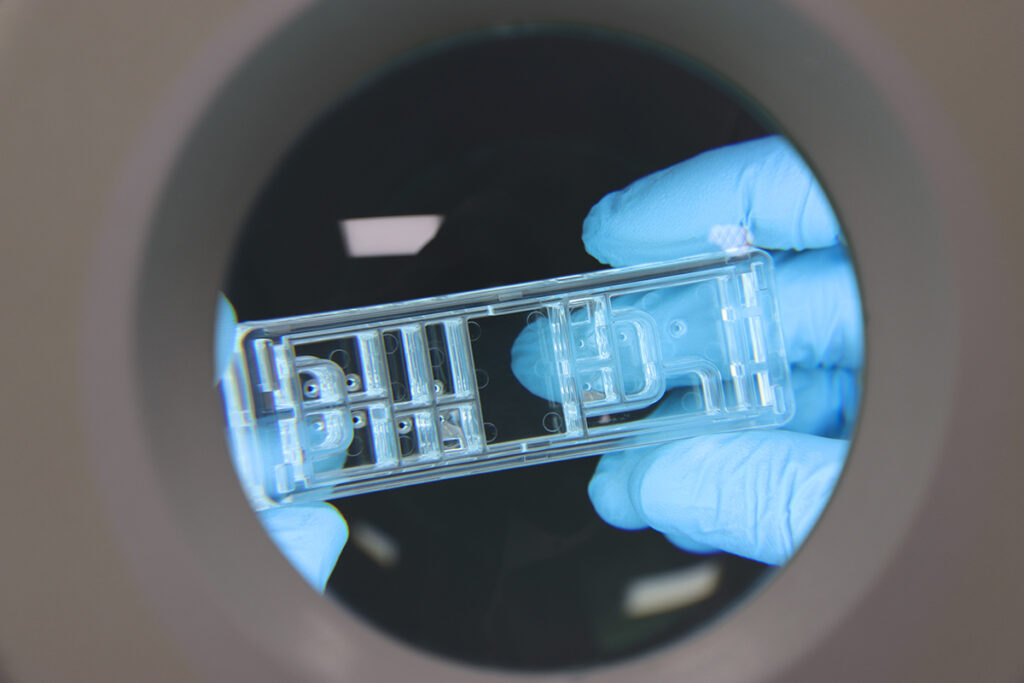

In microfluidic chips manufacturing, the quality of the injection molded part is a driving factor for a good performance of the part. The injected parts needs to have certain conditions to get a perfect bonding of the channel closing systems, such as perfect edges and a good flatness.

For that purpose, several actions are necessary:

- Part redesign for mold inserts manufacturing process

- A proper mold manufacturing process needs to be decided, taking into account the limitation of different technologies, such as nickel inserts, fentosecond laser ablation inserts or micromilling processes.

- The proper tool material will need to be chosen to achieve the desired levels of transparency, roughness, lifetime…

- Part redesign for injection point of view

- The polymer behaviour when freezing has to be taken into account to redesign the part to have a more robust process in achieving the needed bonding conditions, avoiding shrinkage effects.

- Best injection process methodology selection

- Different injection processes can be chosen to get the needed parts. Quality, cycle time, replication requirements, transparency or price can be some factors to decide for going to conventional, variothermal, compression or other injection process methods.

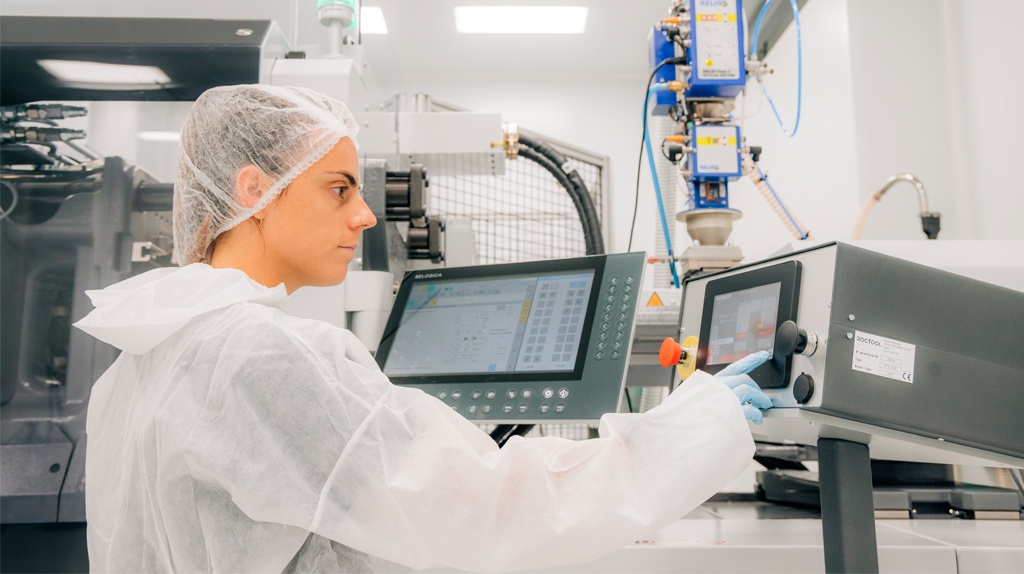

- Best equipment to assure process repeatability

- For a repetitive and trustable quality parts of microfluidic components, high precision and repeatability equipment needs to be chosen not only in the injection machine, but also in all the peripherals needed.

Erreka can help you in all those designs and decisions in your microfluidic components, with redesign, mold manufacture, process definition, and parts injection with the defined quality conditions.

If you have enquiry about this issue dont hesitate to contact us sending an email to medical@erreka.com or by fullfilling the form located at the contact area of the website.

News

We tell you the latest news about ERREKA.

Polymer Science: Driving Innovation in Health and Industry

Polymer science enables the production of devices for a wide range of applications, including biomedical diagnostic (such as point-of-care diagnostics, […]

IVD Raw materials

With the enhancement of medical science and technology, there’s a growing need for real-time diagnostic devices. Many compact systems have […]

From glass chips to polymer chips: revolutionizing microfluidic technology

For many years, glass chips have been integral to biomedical applications, notably in microfluidic technology. However, recent advancements have illuminated […]