From glass chips to polymer chips: revolutionizing microfluidic technology

For many years, glass chips have been integral to biomedical applications, notably in microfluidic technology. However, recent advancements have illuminated that polymers offer comparable or even superior properties, alongside various other advantages. The transition towards polymers in microfluidics is fueled by several factors:

Cost: Polymers are generally more cost-effective than glass, crucial for applications requiring disposable or single-use devices.

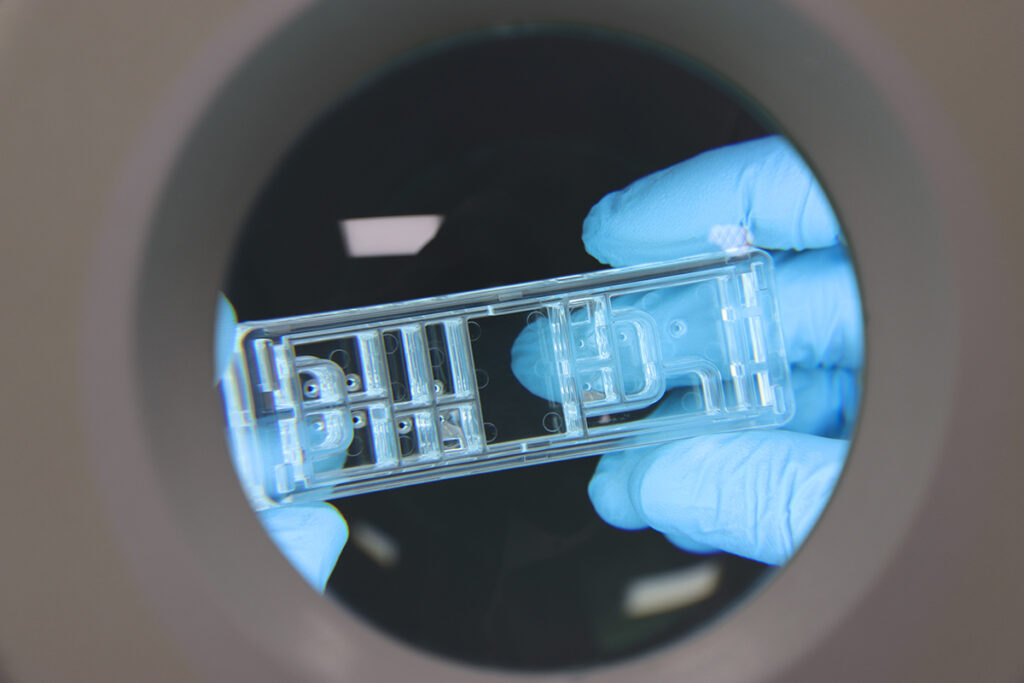

Processability: Polymers are easier to process and manufacture into complex shapes and large quantities, enabling faster and scalable production of microfluidic devices.

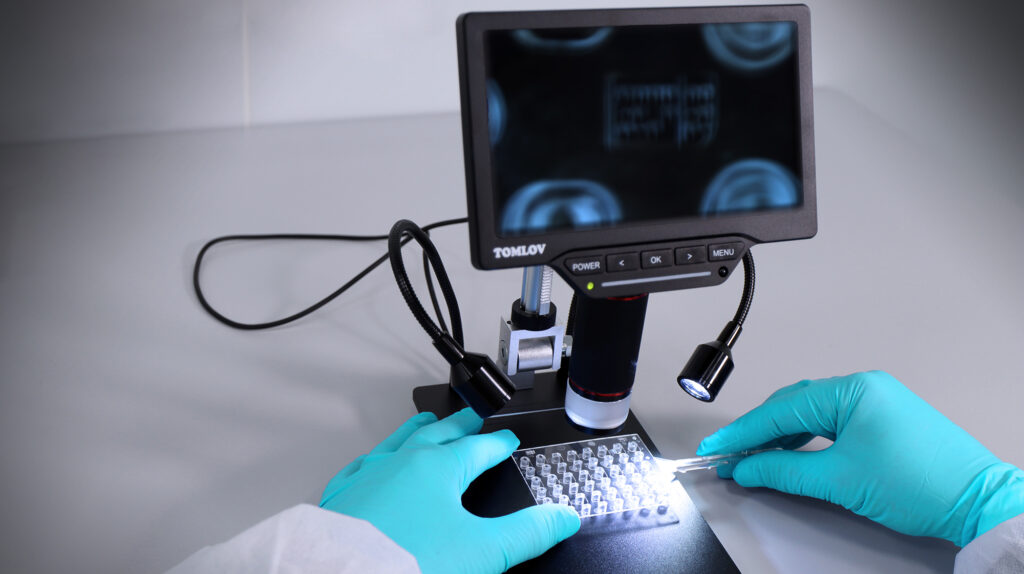

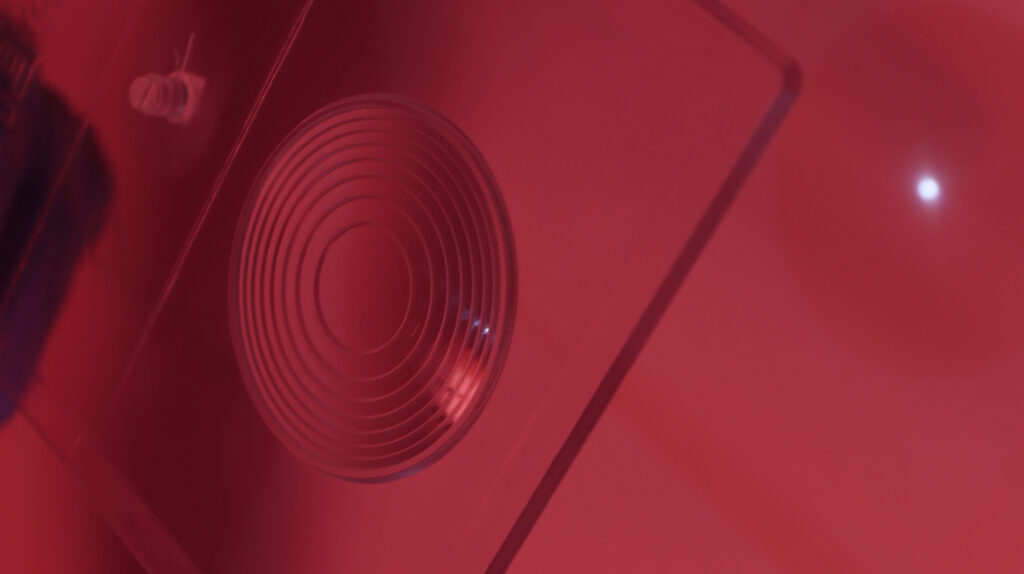

Adequate optical transparency: Many polymers possess optical properties suitable for visual observation in microfluidic applications, such as microscopy.

Compatibility with mass production techniques: Polymers, particularly with processes like injection molding, facilitate large-scale production of microfluidic devices.

Biocompatibility: Polymers offer a wide range of biocompatible options, vital for interactions with living cells or biological tissues, promoting safer and more effective biomedical outcomes.

Moreover, comparing the features of glass and thermoplastic polymers in microfluidic applications:

| Feature | Glass | Thermoplastic polymer |

| Cost | High | Low |

| Fabrication versatiliy | Negative | Moderate |

| Mechanical properties | Good | Good |

| Sterilization | Positive | Positive |

| Oxygen permeability | Negative | Variable |

At Erreka Medical, we emphasize in the selection of the injected materials due to our high-quality manufacturing dedication. The most used thermopolymers are Cyclic Olefin Copolymer (COC) and Cyclic Olefin Polymer (COP) due to their outstanding attributes. With glass-like clarity, superior heat and chemical resistance, and superior purity, these materials exemplify our commitment to excellence in medical manufacturing.

In summary, the transition from glass to polymers in microfluidics is driven by considerations including cost-effectiveness, ease of fabrication, flexibility, optical transparency, biocompatibility, as well as thermal and chemical properties. This shift holds significant promise for advancing microfluidic technologies and enhancing biomedical applications.

News

We tell you the latest news about ERREKA.

Polymer Science: Driving Innovation in Health and Industry

Polymer science enables the production of devices for a wide range of applications, including biomedical diagnostic (such as point-of-care diagnostics, […]

IVD Raw materials

With the enhancement of medical science and technology, there’s a growing need for real-time diagnostic devices. Many compact systems have […]

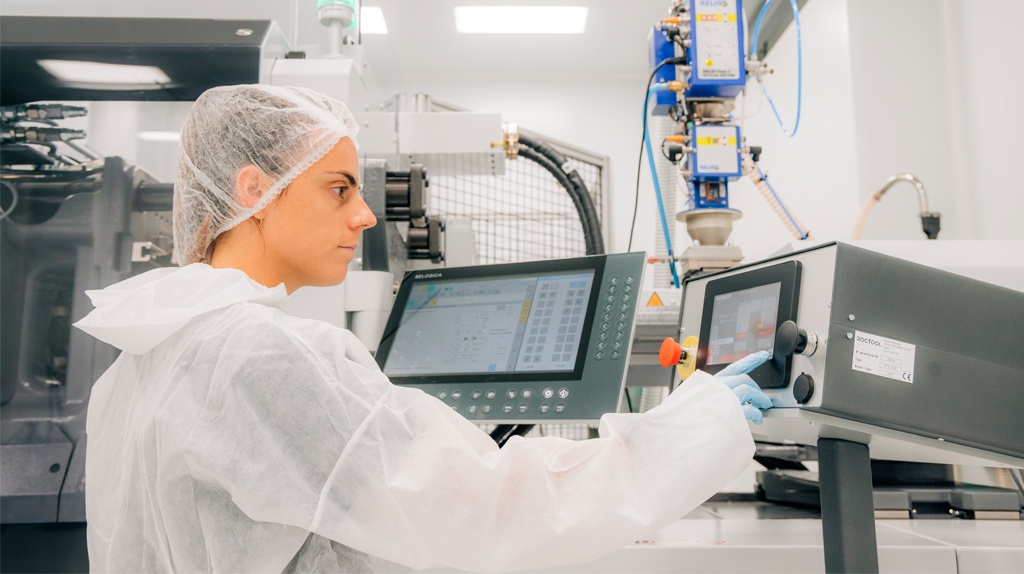

Injection molding microfluidics process definition

In applications involving low stress, thin walls, and microstructure replication, achieving the desired results heavily relies on precisely setting the […]