All the experience of 60 years in industry to be a perfect partner.

Erreka developed different teams and capabilities, to assure the quality and service of the manufactured product to be served. With strong teams in design, automation, process, quality and manufacturing process.

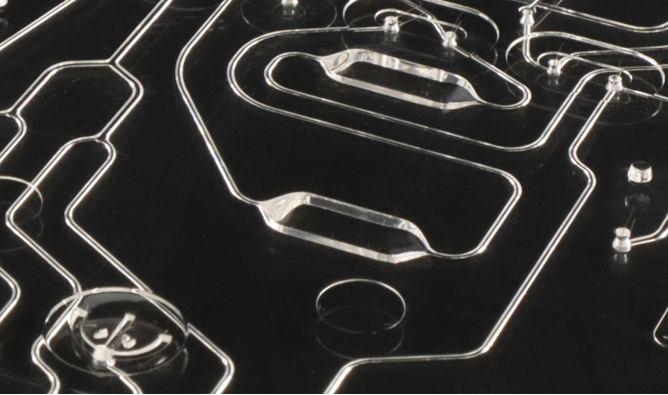

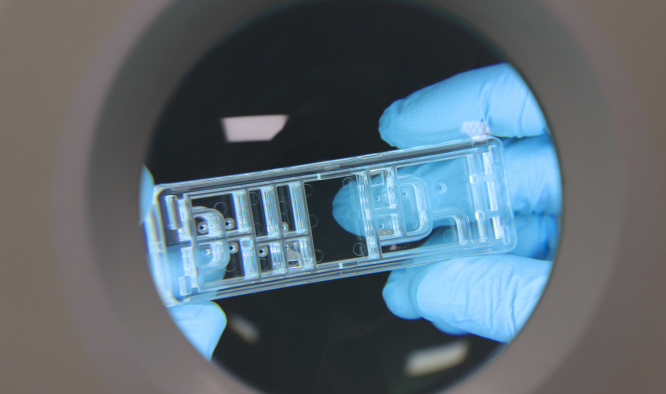

IVD (In Vitro Diagnostics) contract manufacturing plays a pivotal role in the production of medical device components, especially in the realm of diagnostics and therapeutic devices. Securing the right partner for IVD test component is crucial to ensuring the quality, precision, and efficiency required for these critical components.

Partnering with a proficient IVD contract manufacturer offers numerous advantages, such as streamlined production processes, cost-efficiency through economies of scale, and the assurance of consistent, high-quality components. Additionally, collaborating with experts in IVD component fabrication services allows medical device companies to focus on innovation, research, and the development of groundbreaking diagnostic solutions while entrusting the manufacturing intricacies to seasoned professionals.

Arrange a meeting