Technologies

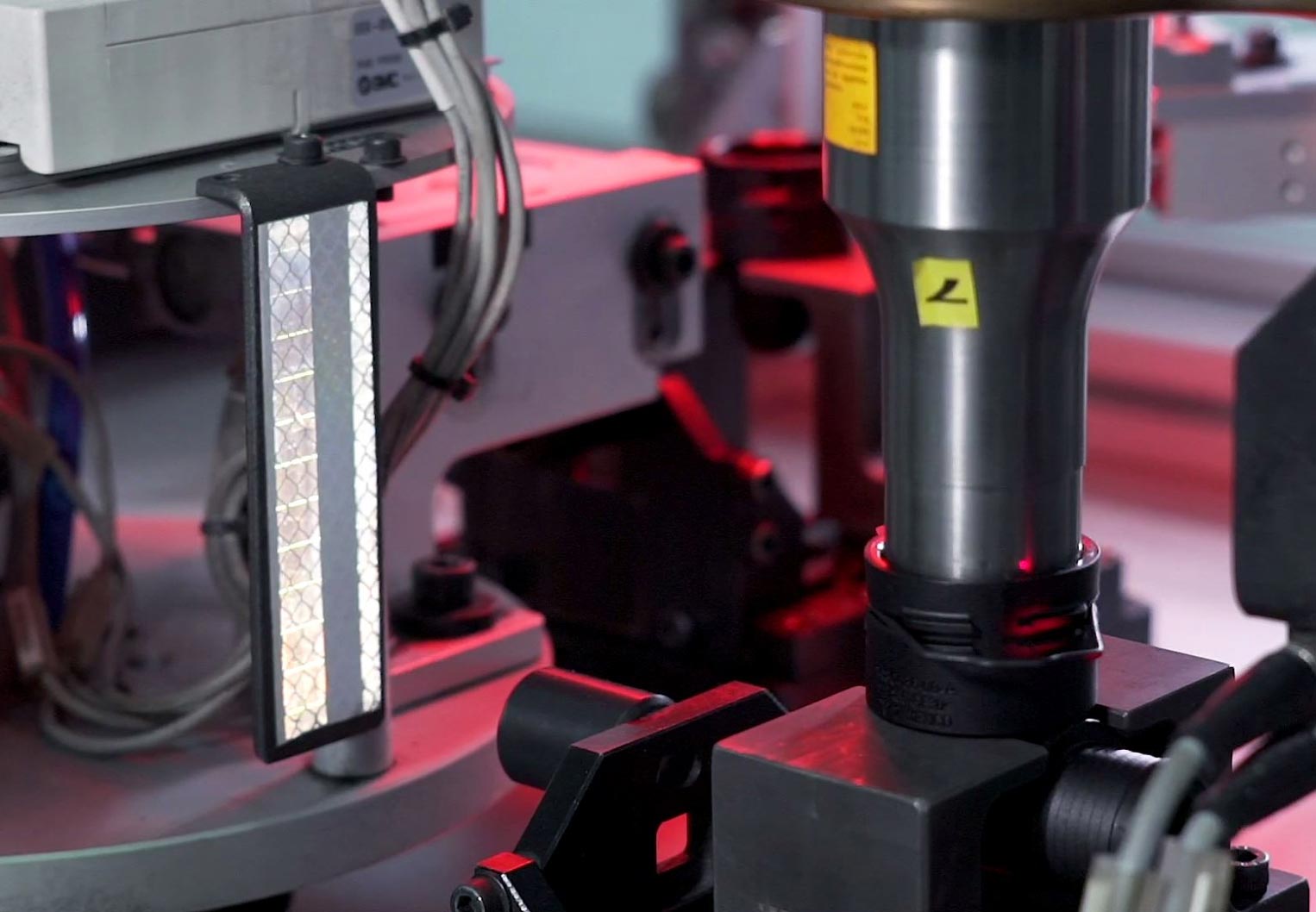

Ultrasonic Welding

It is an ideal bonding technique for medical devices, as it utilizes the device’s own material to form a secure connection without the need for adhesives or glues.

More information BrochureIt is an ideal bonding technique for medical devices, as it utilizes the device’s own material to form a secure connection without the need for adhesives or glues.

More information Brochure

The mentioned process involves high-frequency vibration (ranging from 20 to 40 kilohertz) that melts the material at the juncture of the plastic parts. Both amorphous (e.g., polystyrene) and semi-crystalline (e.g., nylon) thermoplastics are suitable for ultrasonic welding. Ideally, both parts in a weld are made from the same material for optimal results. However, many combinations of unlike plastics can be ultrasonically welded if their melting temperatures are similar.

Ultrasonic weld fixtures play a crucial role in achieving consistently high-quality welds. Their design must carefully consider various factors, including:

Arrange a meeting with us and let’s discuss your situation.