Technology

We are continuously evolving while pioneering new technologies and production processes, stretching ourselves to drive our customers challenges.

Discover technologies

Mastering the latest production technologies is the key to obtaining successful projects.

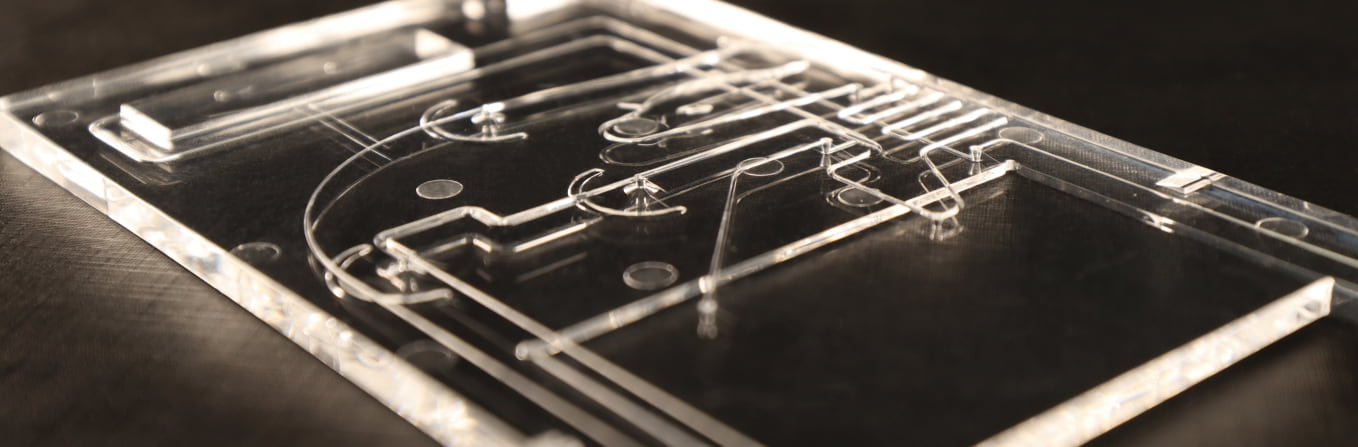

Erreka knows the importance of the technology in the successful design and manufacturing of medical device components, moreover with the complexity of “lab on a chip” and “IVD test ” parts. Joining with the knowledge and experience of the technical team enables Erreka to afford very complex components.

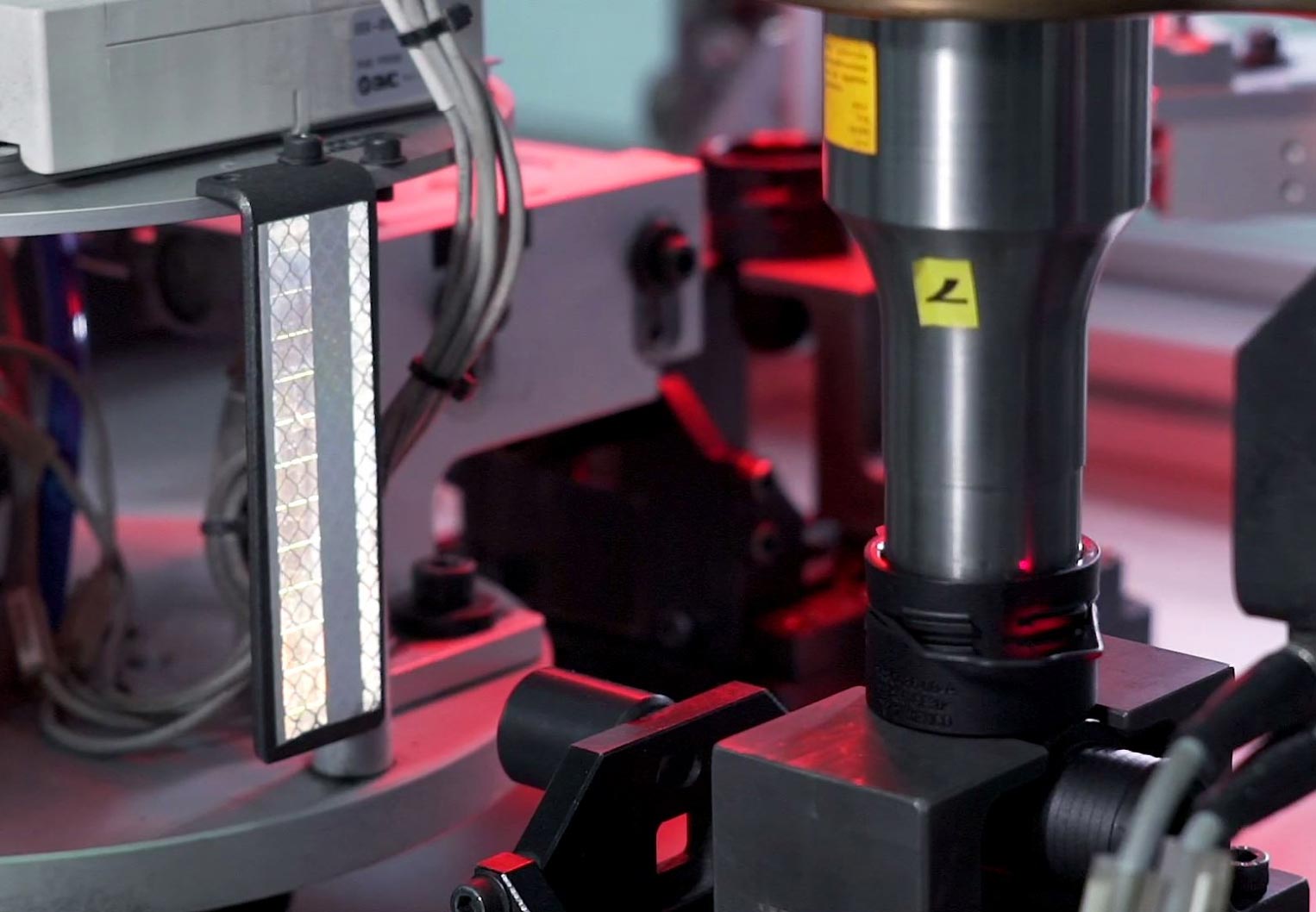

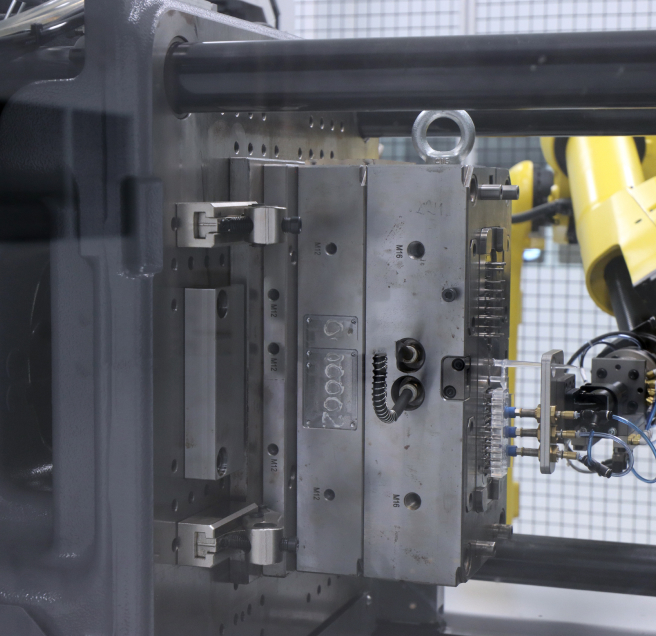

Scientific injection molding

Robust process settings is a key for components quality assurance.

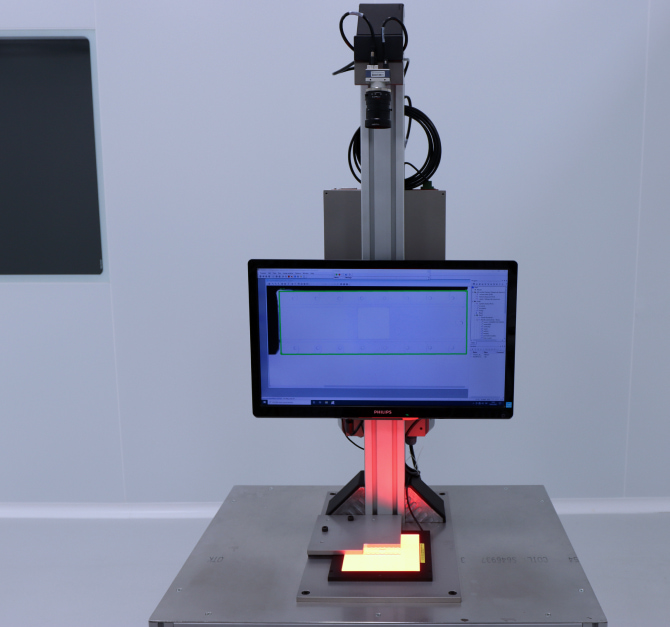

Variotherm injection molding

Induction heat & cool technpology, for high replication rate.

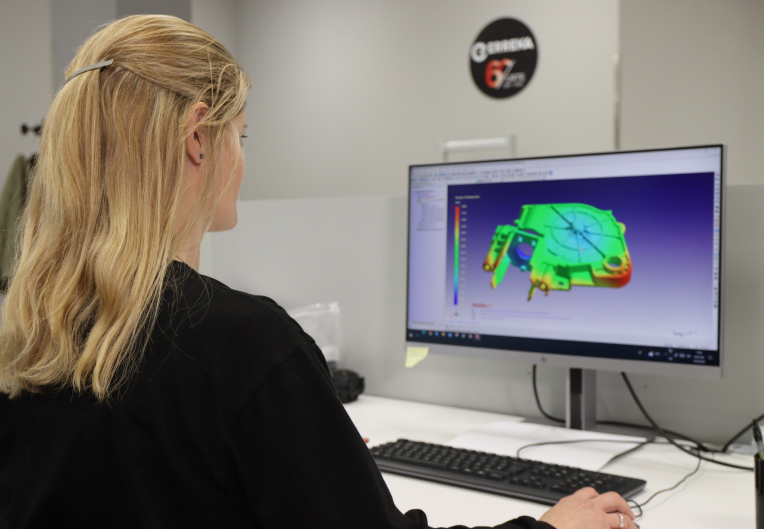

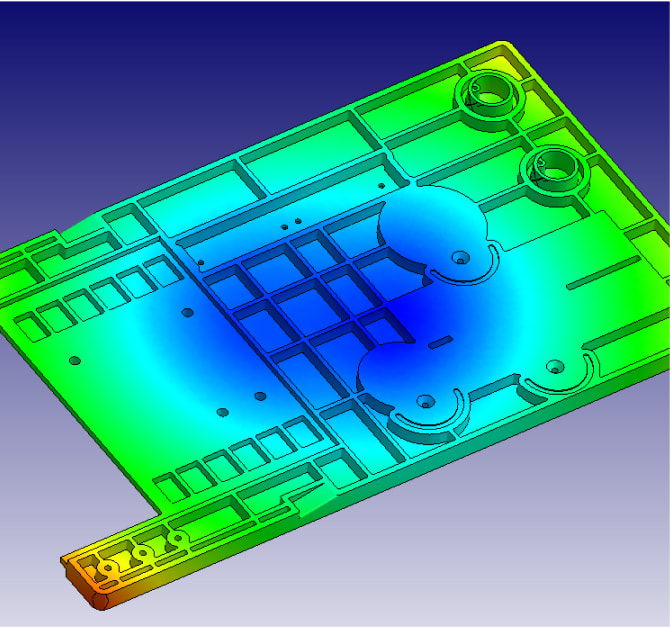

Simulation Injection molding

Injection part complete simulation is a driver for the component design for manufaturing.

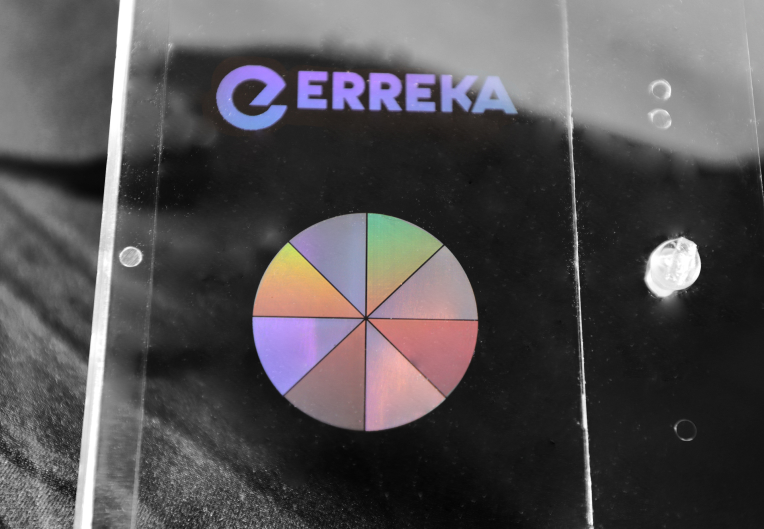

Nano and microstructures

Nano and microstructures replication capabilities to get the most strict microchannels replicas in medical grade Polymers.

Medical injection moulding (cleanroom)

Polymer injection moulding is a cost effective process used to manufacture microfluidic consumables components.

Ultrasonic Welding

It is an ideal bonding technique for medical devices, as it utilizes the device’s own material to form a secure connection without the need for adhesives or glues.